The Proofing Process: Ensuring Perfection from Screen to Paper

Read Time 3 mins

The proofing process in printing is a critical step that ensures the final product meets all expectations before production begins. Proofing helps catch errors, assess design elements, and verify color accuracy. This post will explore the nuances of both digital proofs (sometimes referred to as soft proofs) and printed proofs (sometimes referred to as hard proofs), highlighting their importance and best practices.

Digital/Soft Proofs

These are digital versions of your printed materials that can be reviewed on a computer. Here’s what you need to know about them:

Advantages of Online/Digital Proofs

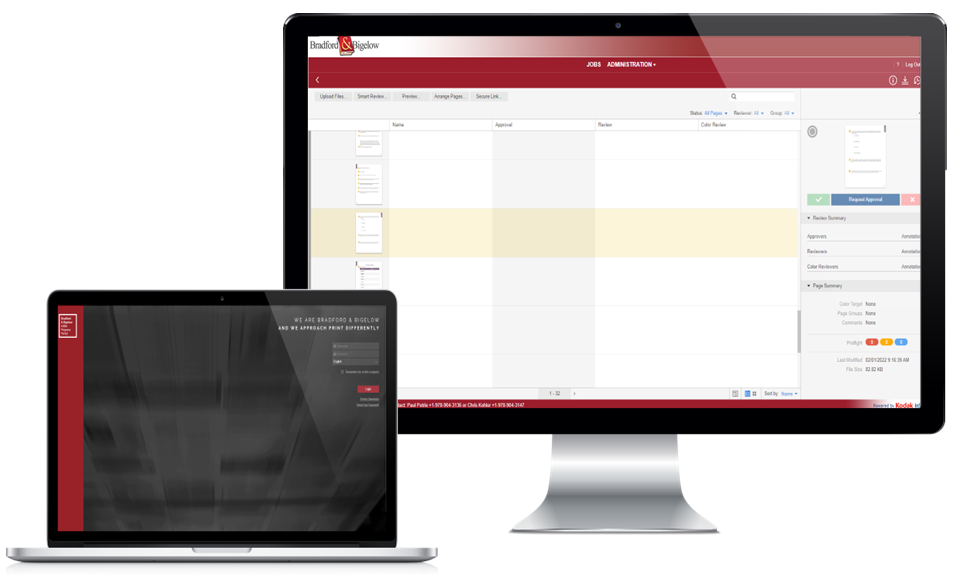

- Speed and Convenience: InSite proofing software can instantly share online proofs. This speeds up the review process significantly compared to traditional methods. Your team can collaborate and provide feedback in real time, reducing turnaround times.

- Cost-Effective: Without the need for physical materials, online proofs save on printing and shipping costs. This makes them more economical, especially for multiple revision projects.

- Environmentally Friendly: By eliminating the need for paper and ink, digital proofs are a greener alternative, contributing to less waste and a smaller carbon footprint.

Best Practices

- High-Resolution Files: Ensure that the digital proof is high resolution, typically 300 dpi, to accurately represent the final print quality. Low-resolution proofs can lead to overlooked issues.

- Color Calibration: Monitors should be color-calibrated to ensure color accuracy. While screens can’t perfectly replicate print colors, calibration helps minimize discrepancies. Colors from screen to paper differ in that the screen color is backlit RGB, while paper reflects light in CMYK. The color gambit of RGB surpasses the limitation of CMYK. It’s always good to convert your work to CMYK before exporting your files. This along with color calibrating your monitor, will ensure the best results.

- Annotations and Feedback: Utilize digital proofing tools that allow for annotations. Clear, concise comments and markups can streamline the review process, making it easier to communicate changes.

- Soft Proofing Software: Use vendors that have reliable soft proofing software that offers features like zoom, side-by-side comparisons, and version tracking. This helps maintain consistency throughout the review process.

Typical cost of soft proofs: free.

Printed/Hard Proofs

While digital proofs are convenient, printed proofs remain indispensable, especially for projects where color accuracy and material quality are paramount. Printed proofs provide a tangible representation of the final product, allowing for a thorough inspection of every detail.

Types of Printed Proofs

- Hard Proofs: These are actual printed samples of the product. Hard proofs are printed digitally on our 60# offset house stock. They can be in signature format or book block.

- Press Proofs: Produced on the actual press and the actual stock, press proofs are the final step before the full print run. They are typically used for large print runs to ensure everything is as required before committing to mass production.

Best Practices for Printed Proofs

- Color Matching: Use Pantone color guides and other color management tools to ensure consistency between digital designs and printed materials and a vendor with a G7 certification. This helps achieve the desired color accuracy.

- Check for Defects: Inspect printed proofs for any defects such as smudges, misalignment, or color inconsistencies. Even minor issues can be magnified in the final print run.

- Paper and Finish Verification: Evaluate the paper type, weight, and finish to ensure they meet your project’s requirements.

- Proof Approval Process: Establish a clear approval process where all stakeholders sign off on the printed proof before proceeding with the full print run. This formalizes the acceptance and reduces the risk of errors.

Typical cost of digital proofs: $.50 for cover and $.25 per page. Typical cost of offset proofs: $25 for cover and $6 per page.

The proofing process, whether digital or printed, is essential for achieving high-quality results. Digital/soft proofs offer speed and cost-efficiency, making them ideal for initial reviews and collaborative feedback. Printed/hard proofs, on the other hand, provide a critical final check for color accuracy and material quality, ensuring the finished product meets your needs.

By understanding and utilizing both types of proofs effectively, you can minimize errors, control costs, and produce materials that align with your vision. The key to successful proofing lies in attention to detail, thorough checks, and clear communication throughout the process. As an ISO 9001:2015 and G7 Certified company, we take quality and color correctness very seriously, ensuring that every print project meets the highest standards of excellence.

Proof costs are not guaranteed and are subject to change. For accurate pricing, please consult your account or business development manager.