Enhancing Covers: A Dive into Varnish, Aqueous, UV, and Film Lamination Cover Coatings

Read Time 3 mins

Cover coatings are essential finishing touches applied to book covers to enhance their appearance, durability, and overall quality. Each type of coating offers distinct characteristics and benefits. Let's explore the differences between four common cover coatings: varnish, aqueous, UV, and film lamination.

Varnish Coating

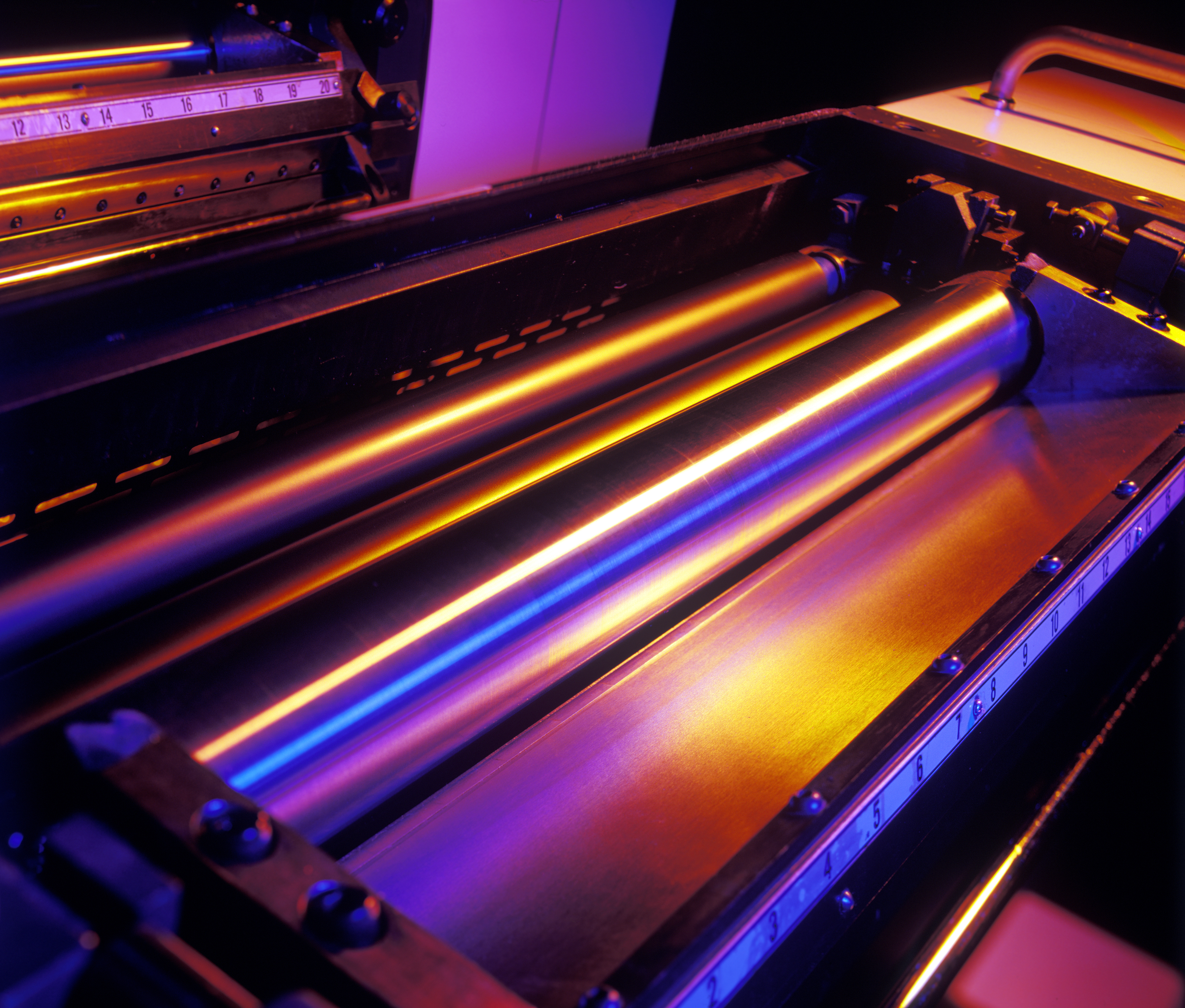

Varnish is a liquid coating that is typically oil-based or solvent-based. It is often applied using a traditional printing press or roller coater. Varnish provides a classic, shiny finish that adds depth and richness to the printed material.

Advantages:

- Offers a high gloss finish, making colors appear vibrant and eye-catching.

- Enhances the appearance of photographs and graphics.

- Suitable for spot varnishing to create specific design effects.

Limitations:

- Longer drying time compared to other coatings.

- Higher levels of VOC emissions, which can be less environmentally friendly.

- Less hard than UV and film lam and ideal for text-weight papers.

Approximate cost per cover: < $.01

Aqueous Coating

Aqueous coating is a water-based coating applied to the printed surface. Aqueous coating provides a smooth, matte or glossy finish, depending on the formulation. The coating dries quickly and is relatively cost-effective, making it a popular choice for many print projects.

Advantages:

- Enhances color vibrancy and contrast.

- Protects against fingerprints and dirt.

- Can be easily written on with certain pens or markers.

Limitations:

- May not offer as high a level of gloss as other coatings.

- Susceptible to smudging until fully dried.

- Not as resistant to extreme conditions like heat or moisture as other coatings.

- Less hard than UV and film lam and ideal for text-weight papers.

Approximate cost per cover: $.0125 - $.015

UV Coating

UV coating is a high-gloss, liquid coating applied to the cover and then cured using ultraviolet light. This process creates a robust and visually appealing finish that is both scratch and chemical resistant.

Advantages:

- Offers an ultra-glossy finish that adds depth and richness to colors.

- Provides excellent protection against wear and tear, making it ideal for products that will be handled frequently.

- Quick curing process allows for faster production times.

- Environmentally friendly with zero VOC emissions.

Limitations:

- A little more expensive compared to aqueous and varnish coatings.

- Can be more challenging to apply uniformly on textured or uneven surfaces.

Approximate cost per cover: $.025 - $.03

Film Lamination

Film lamination involves applying a thin plastic film to the printed material using heat and pressure. This creates a durable and long-lasting protective layer, enhancing the overall quality and durability of the product.

Advantages:

- Provides excellent protection against moisture, stains, tears, and other physical damage.

- Enhances the perceived value and tactile experience of the printed material.

- Ideal for products exposed to harsh environments or frequent handling.

Limitations:

- Higher upfront cost due to the additional materials and production process.

- Adds weight and thickness to the finished product.

- Difficult to apply on irregularly shaped or small-sized items.

Approximate cost per cover: $.07 - $.08

In summary, each cover coating has its unique benefits and considerations, and the choice depends on the specific needs of the print project. While varnish and aqueous coatings are budget-friendly, they are better suited for text-weight papers. Even though film lamination offers the highest level of protection, UV coating offers excellent durability, high quality, and boasts environmental benefits and is the best bang for your buck when it comes to book covers.

*The approximate costs per cover are for demonstration purposes only and are not a guarantee of cost for services. Each project needs to be individually quoted to receive accurate and final pricing.