At Bradford & Bigelow, we often encounter questions about the challenges of inkjet printing, particularly on thin, uncoated paper. Two common issues are waving and cockling. In this blog post, we'll explain why these phenomena occur and how to minimize their impact on your books.

Understanding Waving & Cockling

Waving happens when the paper develops undulating waves, usually along the direction of the paper feed. This can result in uneven printing and distortions in the final image.

Cockling refers to the wrinkling or buckling of the paper surface, which often makes the paper feel rough or uneven to the touch. Cockling can severely affect the appearance and readability of printed materials.

Why Does This Happen?

The primary causes of waving and cockling in inkjet printing on thin, uncoated paper are related to the interaction between the ink and the paper's properties:

- Paper Absorption and Expansion:

- Ink Absorption: Uncoated paper lacks a protective barrier, so the ink is absorbed directly into the fibers. This rapid absorption causes the paper fibers to swell unevenly.

- Moisture Content: As the ink penetrates the paper, it increases the paper's moisture content. Different parts of the paper absorb ink at different rates, leading to irregular expansion.

- Paper Tension and Stress:

- Tension Imbalance: As the ink dries, the paper fibers contract unevenly, creating tension within the paper that leads to distortions.

- Mechanical Stress: Feeding thin paper through an inkjet printer can introduce mechanical stresses that exacerbate waving and cockling.

- Environmental Factors:

- Humidity and Temperature: Variations in environmental conditions can affect how paper behaves during printing. High humidity can increase the paper's moisture content, while temperature fluctuations can influence drying rates.

Choosing the Right Paper for Your Needs

When selecting paper for inkjet printing, there's a tradeoff between cost and the likelihood of experiencing waving and cockling:

Economic Paper

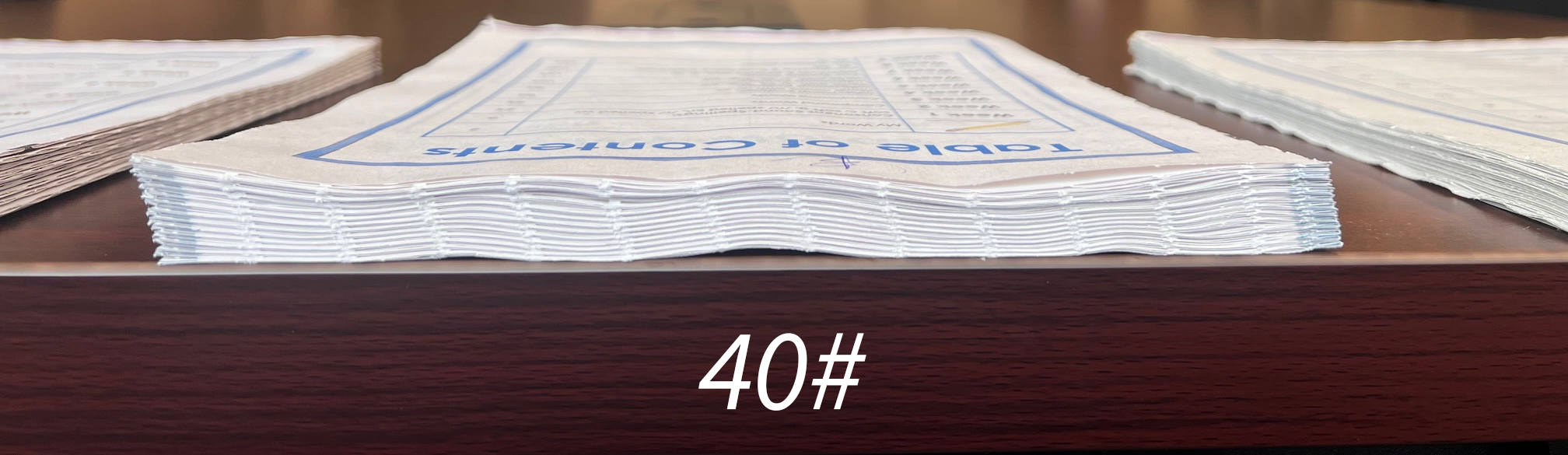

Offset #40 and #42.5: These are more affordable paper options, but they are more prone to waving and cockling due to their thinner and less-treated nature. They are suitable for cost-sensitive projects where minor distortions are acceptable.

Higher-Quality Paper

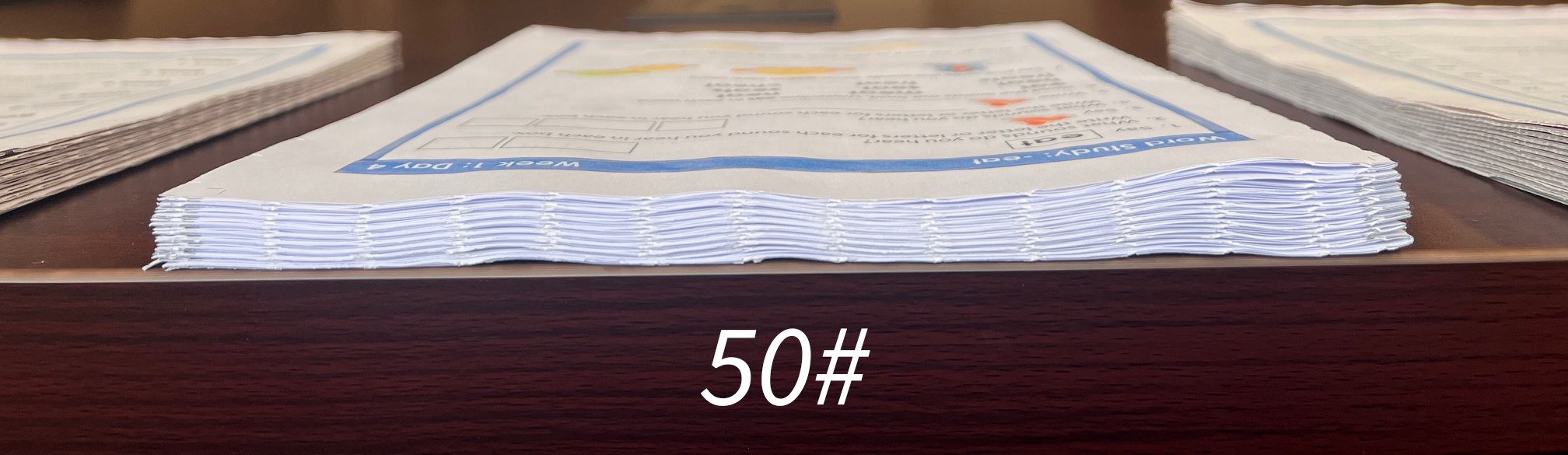

#50 and #60 Treated Paper: These options are more expensive but offer better resistance to waving and cockling. Treated paper is designed to control ink absorption and maintain paper integrity, resulting in smoother and more professional prints. This type of paper is ideal for projects where quality is paramount and minor imperfections cannot be tolerated.

Understanding the causes of waving and cockling in inkjet printing on thin, uncoated paper can help you make informed choices for your printing needs. By balancing cost and quality, you can achieve better results and maintain the quality of your printed materials.